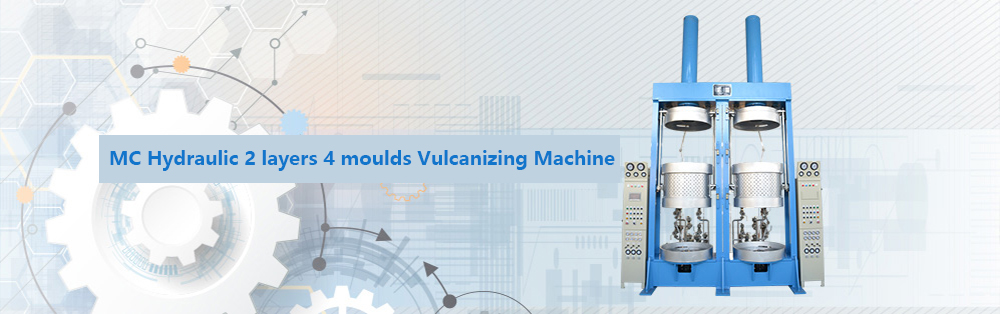

Hydraulic Dual-mould Curing Vulcanizing Machine

•The machine is used to produce all-steel radial tyres for cars.

•The machine is a dual-mould, frame-type, independent units, labyrinth type energy-saving heating plate, B-type full hydraulic center mechanism, on the type of horizontal bar compression lock mode.

•Suitable for nitrogen or steam vulcanization process, can be installed active mould or two half-moulds. Equipped with rear inflatable, storage devices and others.

•The machine hydraulic control system uses a hydraulic station to drive a vulcanizing machine, and can adjust the opening and closing speeds.

•Control system adopts PLC programmable controller as the real-time control core, the industrial computer is man-machine operation interface, can set the vulcanization process parameters, the vulcanization real-time parameter acquisition, the preservation, the alarm and the historical parameter straight inquiry, has the ethernet interface; support the curing machine cluster network.

B1220×1800×2 Hydraulic Dual-mould Curing Vulcanizing Machine

Technical Parameters

|

Description

|

Unit

|

Specifications

|

|

B1220 x 1880 x 2

|

|

Number of Curing Chambers

|

|

2

|

|

Heating Plate Diameter

|

mm

|

Φ1240

|

|

Max Mould Clamping Force

|

KN

|

1800

|

|

Centre Structure Type

|

|

B型

|

|

Suitable Steel Ring Diameter

|

in

|

15-22

|

|

Vulcanized Tyre Diameter (Max)

|

mm

|

Φ900

|

|

Vulcanized Tyre Width (Max)

|

mm

|

350

|

|

Upper Ring Movement

|

mm

|

600

|

|

Lower Ring Movement

|

mm

|

350

|

|

Theoretical Open/Close Time

|

s

|

≤18

|

|

Max hydraulic pressure

|

Mpa

|

21

|

|

External Steam Pressure

|

Mpa

|

1.4

|

|

Internal Steam Pressure

|

Mpa

|

1.8

|

|

Nitrogen Pressure

|

Mpa

|

≤2.8

|

|

Movement pneumatic pressure

|

Mpa

|

0.7

|

|

Control pneumatic pressure

|

Mpa

|

0.35

|

|

Zhejiang ShuTong Industrial Co. Ltd.

Zhejiang ShuTong Industrial Co. Ltd.

Vulcanizing machine

Vulcanizing machine