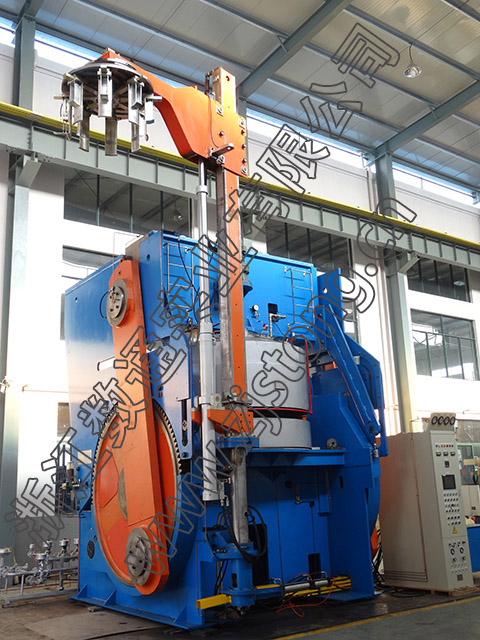

Mechanical Single Mould Curing Vulcanizing Machine

•The machine is used to produce engineering radial tyres and skew tyres; can be used in nitrogen or steam vulcanization process

•The movement is via the vertical lifting of the horizontal beam, the mould is heated by steam, the center of the body is a B-type, equipped with a single-column arm for loading tyres, rear arm structure, electric mould adjustment in accordance to the user's requirements, activate mould drive device, post-inflatable device, inventory, etc., vulcanizing pipe system can be customized.

•The machine adopts PLC programmable controller as the real-time control core, industrial computer as the man-machine interface, can realize the vulcanization process parameter setting, real-time data acquisition, preservation, alarm and historical parameter inquiry, with Ethernet interface, support vulcanizing machine cluster net-working

Technical Parameters

|

Description

|

Unit

|

Specifications

|

|

88"

|

|

Number of Curing Chambers

|

|

1

|

|

Heating Plate Diameter

|

mm

|

2250

|

|

Max Mould Clamping Force

|

KN

|

9510

|

|

Mould Height

|

mm

|

500-920

|

|

Centre Structure Type

|

|

B型

|

|

Suitable Steel Ring Diameter

|

in

|

20-38

|

|

Tyre

Max Diameter

|

Active-Mould

|

mm

|

Φ1600

|

|

Two Halves-Mould

|

mm

|

Φ1880

|

|

Max Tyre Height

|

mm

|

1600

|

|

Theoretical Open/Close time

|

s

|

106

|

|

Vulcanized External Pressure (Max)

|

MPa

|

0.91

|

|

Vulcanized Internal Pressure (Max)

|

MPa

|

2.8

|

|

Movement pneumatic pressure

|

MPa

|

0.7

|

|

Control pneumatic pressure

|

Mpa

|

1.4

|

|

Post Inflation Pressure

|

Mpa

|

1.4

|

|

Zhejiang ShuTong Industrial Co. Ltd.

Zhejiang ShuTong Industrial Co. Ltd.

Vulcanizing machine

Vulcanizing machine