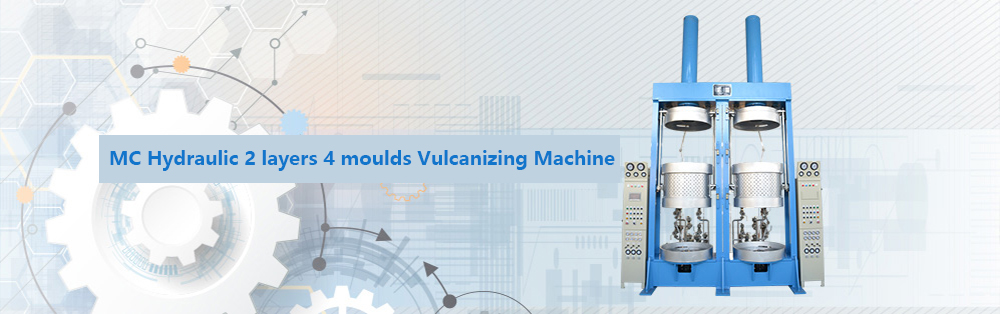

Hydraulic Composite Mould Vulcanizing Machine

•The machine is for the production of large engineering tyres.

•Four fuel cylinders are placed between the base and the lower mould, heating plate and mould are integrated, center structure is B type. The vulcanizing tubes system can be tailor-made per customer’s request

•The machine has the following special features:

---high quality production, least production cost (about only 1/3 of the conventional method), can easily interchange of mould, easy to operate and no intensive labor is involved.

•The control system is using PLC and an industrial computer as a man-machine interface; achieving setting of vulcanizing parameters, centralized management and data retrieving, storing, alarm and history enquires, equipped with ethernet connection and group management of machines possible.

ST-GLL×1-75” Hydraulic Composite Mould Vulcanizing Machine

ST-GLL×1-85” Hydraulic Composite Mould Vulcanizing Machine

TECHNICAL Parameters:

|

Description

|

Unit

|

Specifications

|

|

|

Ø75”

|

Ø85”

|

|

Number of Curing Chambers

|

|

1

|

1

|

|

Max Mould Diameter

|

mm

|

Φ1820

|

Φ2070

|

|

Max Mould Clamping Force

|

KN

|

6720

|

9650

|

|

Suitable Product Spec

|

Cross Section Width

|

mm

|

270-570

|

400-650

|

|

External Diameter

|

mm

|

≤1620

|

≤1810

|

|

Rubber Cavity Max Extended Height

|

mm

|

1200

|

1600

|

|

Vulcanized External Pressure (Max)

|

MPa

|

0.8

|

0.8

|

|

Vulcanized Internal Pressure (Max)

|

MPa

|

0.15

|

0.15

|

|

Vulcanized Internal Hot Water Pressure

|

MPa

|

3

|

3

|

|

Cooling Water Pressure

|

MPa

|

2.5

|

2.5

|

|

Control pneumatic pressure

|

MPa

|

0.4

|

0.4

|

|

Zhejiang ShuTong Industrial Co. Ltd.

Zhejiang ShuTong Industrial Co. Ltd.

Vulcanizing machine

Vulcanizing machine