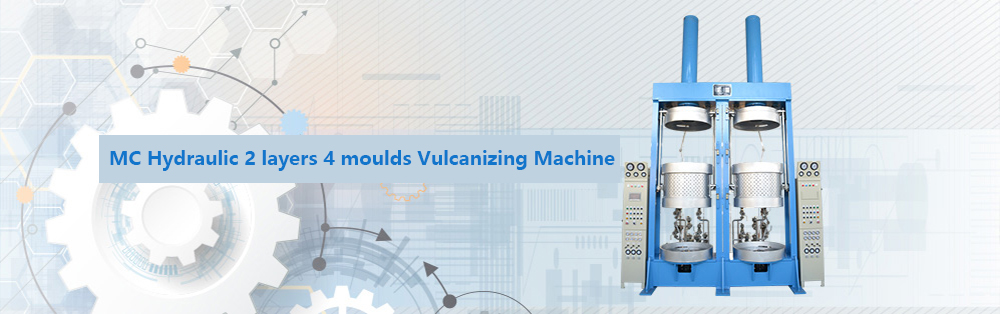

Hydraulic Multilayer Vulcanizing Machine

•The machine is suitable for the production of various bicycle tyres.

•The two-stage fuel cylinder is placed in the center of the lower beam and is in the form of a bottom-up mould, each with five to six work-stations,

•The moulds are opened/closed along linear guide rail; the moulds are heated by heating plates

•One hydraulic station can serve 7 or 8 vulcanizing machines.

The control system is using PLC and an industrial computer as a man-machine interface; achieving setting of vulcanizing parameters, centralized management and data retrieving, storing, alarm and history enquires.

LLY-745×530×5 Hydraulic Multilayer Vulcanizing Machine

LLY-840×530×5 Hydraulic Multilayer Vulcanizing Machine

Technical Parameters

|

Description

|

Unit

|

Specifications

|

|

Ø745

|

Φ840

|

|

Number of Curing Chambers

|

|

5

|

5

|

|

Heating Plate Diameter

|

mm

|

Φ745

|

Φ840

|

|

Max Mould Clamping Force

|

KN

|

530

|

530

|

|

Mould Height

|

mm

|

≤110

|

≤110

|

|

Suitable Steel Ring Diameter

|

in

|

10-18

|

16-28

|

|

Theoretical Open/Close time

|

s

|

18-22

|

18-22

|

|

Max hydraulic pressure

|

MPa

|

21

|

21

|

|

Vulcanized Outside Pressure (Max)

|

MPa

|

0.8

|

0.8

|

|

Vulcanized Inside Pressure (Max)

|

MPa

|

0.8

|

0.8

|

|

Movement pneumatic pressure

|

MPa

|

0.7

|

0.7

|

|

Control pneumatic pressure

|

MPa

|

0.35

|

0.35

|

|

Zhejiang ShuTong Industrial Co. Ltd.

Zhejiang ShuTong Industrial Co. Ltd.

Vulcanizing machine

Vulcanizing machine