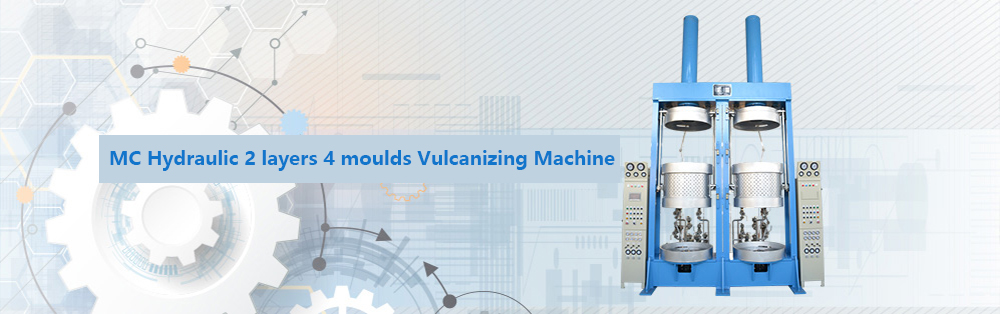

Hydraulic Four-moulds Curing Vulcanizing Machine

•The machine is used in tyres for motorcycles & electric cars and oblique tyres, suitable for nitrogen or steam vulcanization process.

•The framework is welded in two pieces with two moulds each, screwed together to form one with four moulds, the fuel cylinder is placed in the center of the upper beam. The moulds are opened/closed along linear guide rail; the moulds are heated by heating plates, center structure is B type. The vulcanizing tubes system can be tailor-made per customer’s request while “post-inflation” station is an option..

•The hydraulic process is using frequency conversion system which is over 30% energy efficient than the conventional system. One hydraulic station can serve 5 vulcanizing machines and can achieve open/close mould speed adjustment function.

•The control system is using PLC and an industrial computer as a man-machine interface; achieving setting of vulcanizing parameters, centralized management and data retrieving, storing, alarm and history enquires, equipped with ethernet connection and group management of machines possible.

LLY-B815×1000×4 Hydraulic 4-moulds Curing Vulcanizing Machine

LLY-B915×1000×4 Hydraulic 4-moulds Curing Vulcanizing Machine

Technical Parameters

|

Description

|

Unit

|

Specifications

|

|

B815

|

B915

|

|

Number of Curing Chambers

|

|

4

|

4

|

|

Heating Plate Diameter

|

mm

|

Φ815

|

Φ915

|

|

Max Mould Clamping Force

|

KN

|

1000

|

1000

|

|

Mould Height

|

mm

|

105-300

|

140-300

|

|

Centre Structure Type

|

|

B (Oil pneumatic)

|

B (Oil pneumatic)

|

|

Suitable Steel Ring Diameter

|

in

|

8-18

|

8-18

|

|

Wheel Outer Diameter (max)

|

mm

|

Φ700

|

Φ750

|

|

Vulcanized thickness (max)

|

mm

|

300

|

300

|

|

Tyre Height (max)

|

mm

|

500

|

550

|

|

Theoretical Open/Close time

|

s

|

18-22

|

18-22

|

|

Max hydraulic pressure

|

MPa

|

21

|

21

|

|

External Pressure

|

MPa

|

1.4

|

1.4

|

|

Internal Pressure

|

MPa

|

2.4

|

2.4

|

|

Movement pneumatic pressure

|

MPa

|

0.7

|

0.7

|

|

Control pneumatic pressure

|

MPa

|

0.35

|

0.35

|

|

Zhejiang ShuTong Industrial Co. Ltd.

Zhejiang ShuTong Industrial Co. Ltd.

Vulcanizing machine

Vulcanizing machine